Our process modeling software program in the size-up Suite enables you to achieve these plans and accelerate process improvement though working with progressively complex processes.

Attain insight into response mechanisms for deep reaction knowledge that may be leveraged for exceptional processing

Backed by our fantastic user assist and coaching, Scale-up Suite empowers corporations to gain deep process expertise and achieve profitable producing of their solutions.

Scale-up Suite�?is a leading supplier of process progress software package for the global pharmaceutical and chemical industries.

Use mechanistic types to forecast conditions that increase produce and lower impurities in synthetic natural processes

Predict the performance of every unit operation ahead of Each individual campaign to make certain results on scale-up from lab to plant.

Transferring a process throughout scales will frequently effect the Bodily premiums during the synthesis, such as mixing, heat transfer, and mass transfer. Comprehending the effect of those charges on the process is essential to coming up with the process to function successfully and robustly when manufacturing high-quality products and solutions at new scales.

Quickly develop response kinetic styles from chemical instinct and common lab information to style optimal reactions.

Our process modeling software program in the Scale-up Suite presents a fairly easy-to-use and detailed platform for creating calculations and performing simulations that can account with the Bodily prices, ensuring a ideal to start with time scale-up and thriving tech transfer.

We've been devoted to continuing to deliver the wonderful merchandise and client assistance that our prospects have arrive at be expecting from Scale-up Devices and anticipate including the worldwide strengths of METTLER TOLEDO.

Process calculations and simulations which might be applied across all scales, enabling accelerated enhancement and appropriate initial time scale-up.

The mix of our extensively made use of Scale-up Suite�?process growth and scale-up software with METTLER TOLEDO's current market-top services and products for Organic and chemical process advancement makes one of the most in depth offerings for these significant applications while in the pharmaceutical and chemical field.

Mixing calculation equipment help scale from lab reactors website for example Ambr® fifteen, shake flasks, vials, and rocked/wave bags to stirred tank reactors

Being a chemical process is developed, far more material has to be manufactured to ultimately obtain business production requires.

METTLER TOLEDO is dedicated to not only preserving carbon neutrality for our operations but in addition to developing science-centered targets to travel an complete reduction of greenhouse fuel emissions throughout our click here functions and get more info provide chain.

Intensive library of All set-to-use simulation resources produced by market authorities, available to all end users

Speedily completely transform routinely gathered process, PAT, and offline analytical knowledge into kinetic types that permit better reaction comprehending with limited time and materials

Establish bioreactor products to guidance the prediction of glucose and DO degrees, pH, click here and titer at Every single scale, leveraging mixing equipment to make certain uniform spatial distribution

Browse a tailor made portfolio, entry rates, Production of chemical process package and handle your mounted devices on our extended electronic platform.

Process scale-up typically refers to increasing the production potential by running a chemical process in greater equipment. For instance, transferring a process from the lab scale to your pilot plant or from a pilot plant to an entire-scale production plant.

Often, a chemical process is scaled up many occasions, around orders of magnitude, from modest lab bench scale to medium pilot plant facilities to massive complete-scale production crops.

Assure sufficient mixing without the need of extreme shear in functions starting from media improvement/prep to UF/DF, preventing batch failures and yield reduction

Bradley Pierce Then & Now!

Bradley Pierce Then & Now! Brian Bonsall Then & Now!

Brian Bonsall Then & Now! Brandy Then & Now!

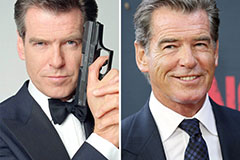

Brandy Then & Now! Pierce Brosnan Then & Now!

Pierce Brosnan Then & Now! Nicki Minaj Then & Now!

Nicki Minaj Then & Now!